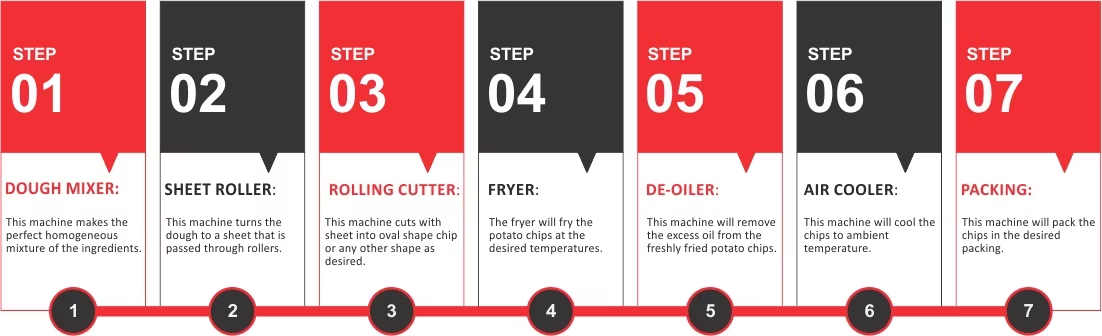

The working of the Potato chips frying machine line is automated, right from mixing and cutting to packaging. The frying duration and the frying temperature can be adjusted to get crunchy and crispy fried chips.

*All our processing lines are custom made and the above list is just to comprehend the process.

1) Dough Preparation:

The dough or mixture for the potato chips is prepared by mixing cooked potato solids with water and other ingredients. This mixture helps bind the potatoes together and gives the chips their desired texture.

2) Rolling

The prepared dough is fed into a rolling machine, which consists of two or more rollers. The rollers press the dough, gradually reducing its thickness and forming a thin sheet. The rolling process ensures that the dough is evenly spread and of uniform thickness.

3) Cutting and Forming

After the dough is rolled into a thin sheet, it is then fed into a cutting machine. The cutting machine is designed to cut the sheet of dough into the desired shape of the potato chips. This can be achieved using various cutting mechanisms, such as rotary blades or molds.

As the dough sheet is cut into individual chips, the chips take shape based on the design of the cutting machine. This forming process creates the distinctive shape of the potato chips, such as flat, wavy, or ridged.

4) Fryer

The temperature of the fryer can be set manually. In this machine, the potatoes will be fried at a desired level such that, the potato chips are tasty, yummy and crispy.

5) De-Oiler

There are lots of people who munch on crispy fried potato chips. After the frying process, the fried chips are quite oily. To remove the excess oil, this unique de-oiling machine is used which is highly efficient and fast. This machine also reduces the labour requirement, and enhances the working conditions.

6) Air cooler

The hot fried oil-free chips are cooled down to ambient temperature in this air cooling machine before sending it to the last stage i.e. packing

7) Packing

This is the final stage in the potato chips frying machine line. The potato chips are packed in such a

manner, so as to maintain their crispiness, and are protected from getting oxidized.

Remember to consult with experts and professionals at Snactek to tailor these lines to your specific needs and industry requirements. Embrace the potential of an optimized food manufacturing line, and unlock the benefits of improved efficiency and productivity in your operations.